The Facts About Roof Nuts Revealed

Table of ContentsWhat Does Roof Nuts Do?The Greatest Guide To Roof NutsUnknown Facts About Roof Nuts10 Simple Techniques For Roof Nuts

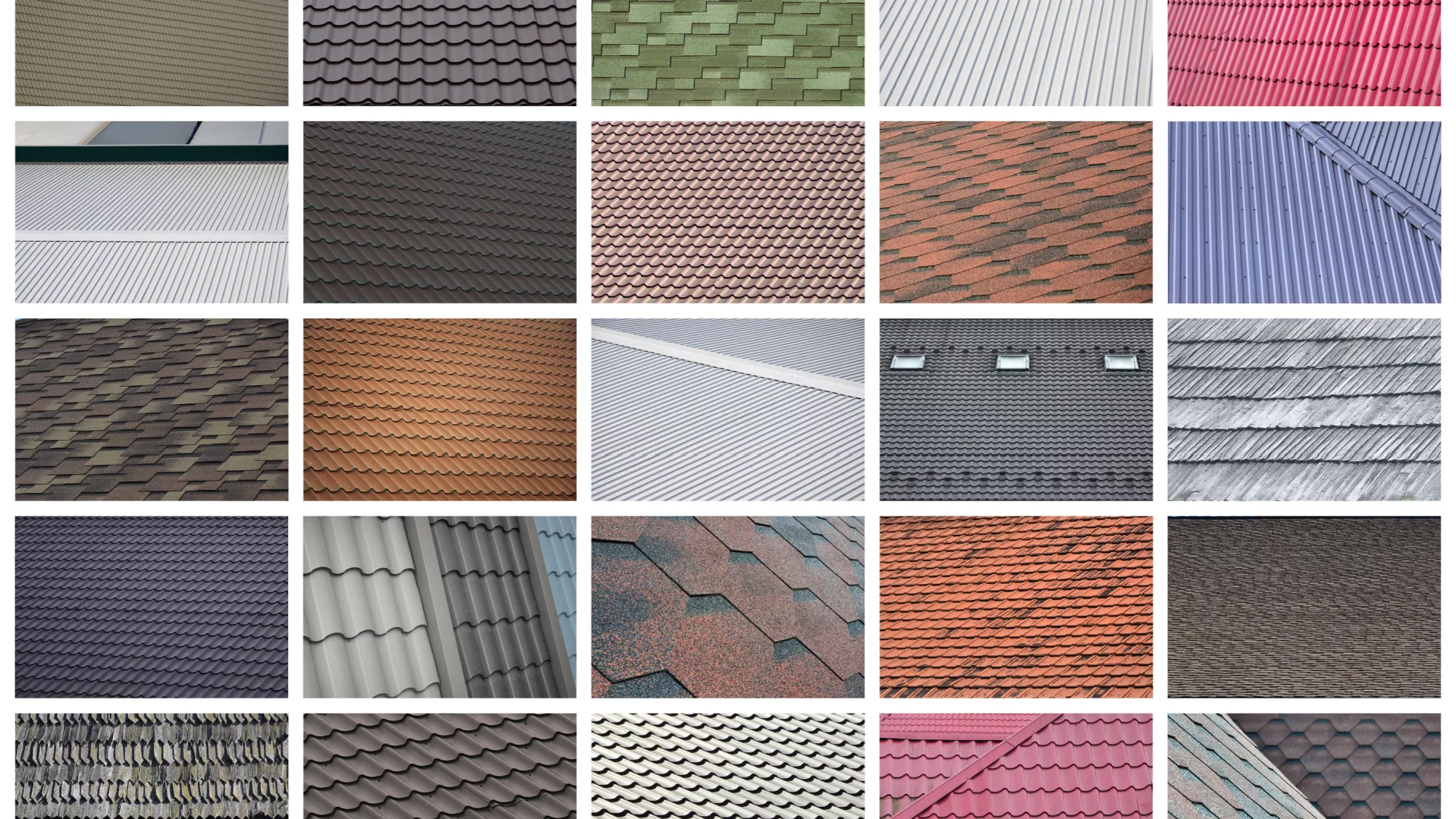

Made from a synthetic polycarbonate layer integrated with enhancing scrim, TPO roofing is mounted making use of warm welding, developing a strong and long lasting bond with the roof covering deck. This method of setup ensures that TPO roof coverings can last as much as 25 years with proper care and maintenance. TPO roof material is readily available in various sizes, making it versatile for various level roof covering applications. PVC roof is not recommended for high slopes, as well as areas with hefty snowfall or freeze-thaw cycles. PVC roof combines toughness with ease of installment, making it a prominent choice for numerous level roofing applications.These systems, additionally referred to as accumulated roofing, are made up of several layers of asphalt-impregnated roofing really felt and asphalt, developing a durable and watertight obstacle versus the components. The leading layer usually includes carefully crushed rock granules, giving a wear-resistant surface that can withstand the rigors of time. The methodical application process of BUR guarantees proper adhesion of each layer, hence improving the roofing system's general sturdiness and durability.

Things about Roof Nuts

In addition, BUR is understood for its cost-effectiveness, providing an affordable price per year of anticipated service life contrasted to various other commercial roof systems. With a life expectancy varying from 15 to 30 years, BUR offers a reliable and long-lasting roofing solution for both residential and industrial buildings. Its capability to manage various climate conditions and its cost-effectiveness make BUR an attractive choice for numerous residential or commercial property owners.

thanks to the addition of special polymers. This asphalt-based material is modified to enhance its flexibility and durability, making it suitable for a wide variety of environments and applications. Changed bitumen roofing is manufactured right into rolls with either smooth or granulated surface areas, giving different options for various roofing needs. There are various sorts of modified asphalt roofing, with typical polymers such as atactic polypropylene (APPLICATION) and styrene butadiene styrene (SBS) made use of in the cap sheet.

With proper installment and maintenance, customized bitumen roof can last in between 20 and three decades - https://canvas.instructure.com/eportfolios/3884470/home/roof-nuts-your-all-in-one-commercial-and-residential-roofing-solution-in-georgia-introduction-georgia-roofs-deserve-better-heres-why. Changed bitumen roof covering can be installed making use of numerous techniques, each offering its very own advantages. The torch-applied technique entails heating up the underside of the roof covering material with a propane lantern to stick it to the substrate. The cold adhesive technique entails using a specially formulated glue to the substrate prior to laying down the changed bitumen sheets. There are additionally self-adhesive modified bitumen sheets that come with a pre-applied glue layer, removing the requirement for open flames during installation. Each method has its benefits, but all need skilled professionals to make sure ideal efficiency and longevity

The 4-Minute Rule for Roof Nuts

Steel level roofing can last up to 35 years in optimal conditions, making it a trusted long-term investment. One of the major drawbacks of steel roof covering is its higher initial expense contrasted to various other roof covering products.

Fluid roof has a fairly uncomplicated application process that guarantees smooth, efficient protection. These systems can be put on a selection of surface areas, consisting of metal, BUR, and single-ply membranes. The adhering to subsections will explore the various sorts of liquid coverings and the application procedure carefully. There are several sorts of fluid finishings used in roof covering, each offering distinct benefits: Silicone finishings master climate resistance and can endure ponding water without deteriorating.

Roof Nuts - An Overview

The roof surface area must be extensively cleaned up and repaired to remove any particles, dust, or damaged locations that might impede the covering's performance. This prep work phase is critical as it sets the structure for a seamless and resilient roof covering layer. When the surface is all set, the fluid coating is normally used utilizing spray equipment or rollers for even insurance coverage.

The average life-span of a level roof has to do with twenty years, which affects the total value originated from the first investment. Labor prices are a substantial part of repair service expenses and can considerably affect the long-lasting worth of a level roofing system - https://share.evernote.com/note/9f09f7e5-db64-650d-7d07-78fa10397b95. Investing in a long lasting and resilient roof product can conserve cash over time by reducing the frequency and price of repair work and maintenance